Introduction to De-Ice and Anti-Ice Systems

Adverse weather conditions are one of the biggest challenges in aviation, especially when it comes to ice accumulation on aircraft surfaces. In executive aircraft, which often operate at altitudes and routes where these conditions are common, de-ice and anti-ice systems play a crucial role in ensuring flight safety and efficiency. These systems prevent ice from building up on critical aircraft surfaces like wings, tail, and engines, maintaining performance and maneuverability.

The Difference Between De-Ice and Anti-Ice Systems

The de-ice system is designed to remove ice that has already formed on the aircraft’s surfaces, while the anti-ice system prevents ice formation before it can occur. Both systems are essential for safe operation in freezing conditions, but they work in different ways:

- De-Ice: The de-ice system activates when ice has already formed, using methods such as inflatable rubber boots on the leading edges of the wings, which expand and contract to break the ice.

- Anti-Ice: The anti-ice system is preventive, applying heat or chemicals to surfaces to prevent ice from forming. A common example is using hot air from the engines to heat the edges of the wings.

Main Components of the Systems

De-Ice Systems

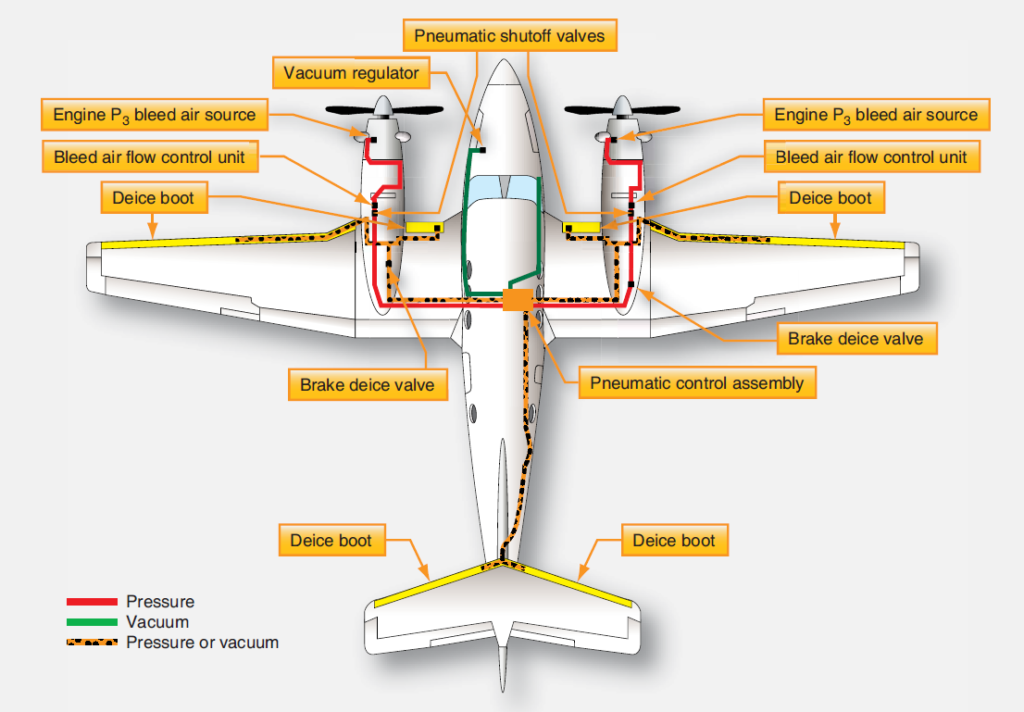

- Pneumatic Boots: These are rubber structures located on the leading edges of the wings and horizontal stabilizer. When ice forms, these boots inflate, breaking the ice and allowing it to be carried away by the airflow.

- Electrical Elements: Some systems use heat generated by electric resistance to melt the ice, especially on propellers and windshields.

Anti-Ice Systems

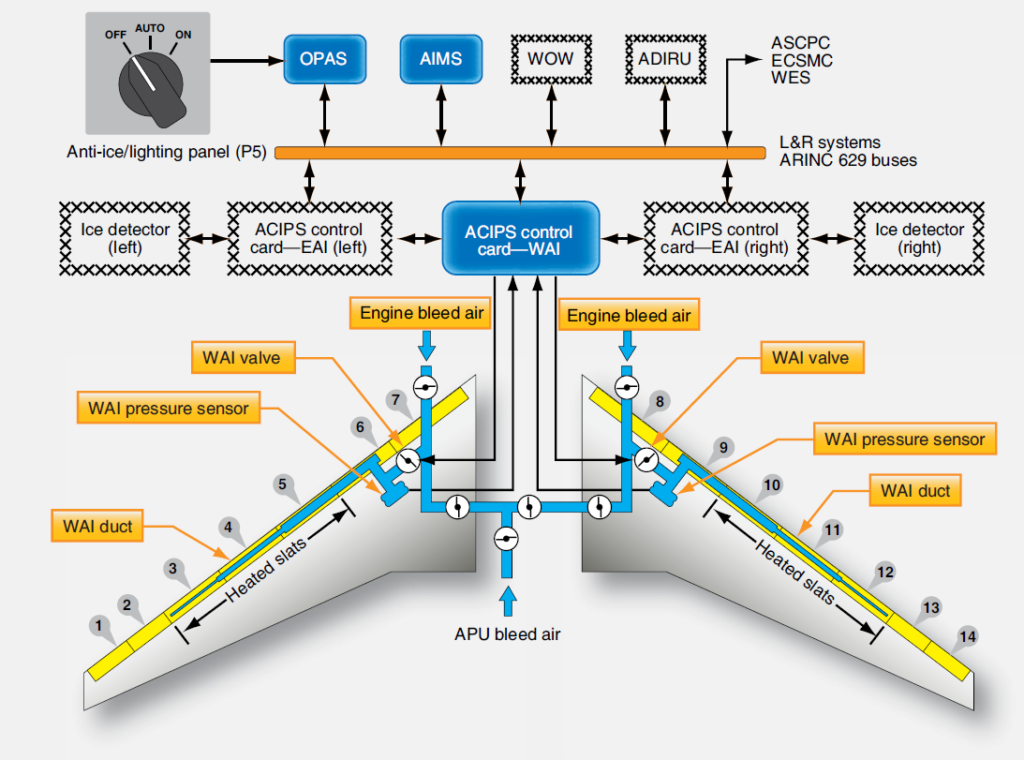

- Engine Bleed Air: Commonly found in jet aircraft, the anti-ice system uses hot air from the engine compressor, which is channeled to the wing edges, engine inlets, and even the radome.

- Anti-Icing Fluids: In some cases, fluids like glycol are applied to aircraft surfaces, creating a protective barrier that prevents ice from forming.

- Electrical Heating: Similar to de-ice systems, electrical heating can also be used to prevent icing on sensitive areas, such as probes and sensors.

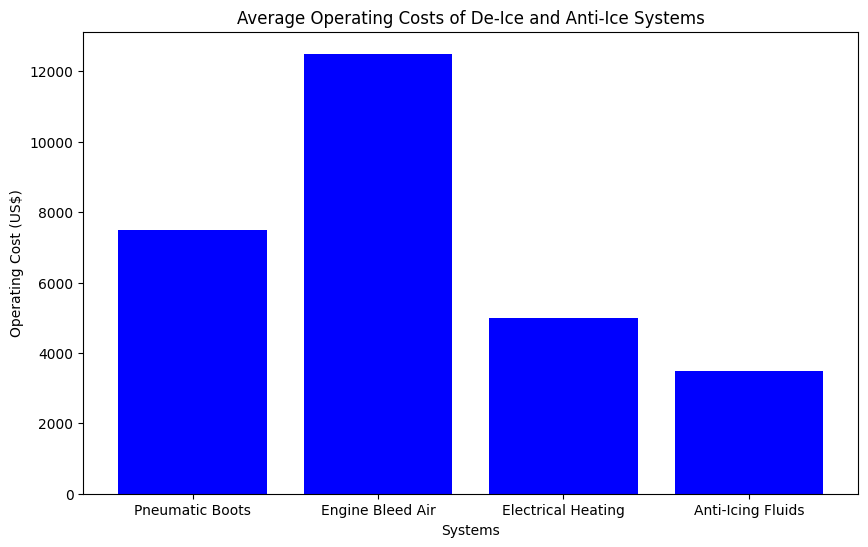

Operational Costs of De-Ice and Anti-Ice Systems

While these systems are essential, their use can increase the operational costs of an executive aircraft. Regular maintenance is required to ensure that these systems work correctly. The costs vary depending on the aircraft and the system used:

| System Type | Average Operating Cost (Annual) |

|---|---|

| Pneumatic Boots | $5,000 – $10,000 |

| Engine Bleed Air | $10,000 – $15,000 |

| Electrical Heating | $3,000 – $7,000 |

| Anti-Icing Fluids | $2,000 – $5,000 |

Bar Chart Comparing Operational Costs

Advanced Avionics and Ice Protection Systems

Modern executive aircraft, such as the Gulfstream G700 and the Bombardier Global 7500, come equipped with advanced avionics that integrate de-ice and anti-ice systems efficiently. Through Flight Management Systems (FMS), pilots can monitor real-time ice detection and adjust heating systems accordingly. Additionally, advanced ice sensors automatically detect when the system needs to be activated, ensuring efficiency during all flight phases.

Specifications Table: De-Ice and Anti-Ice Systems

| Aircraft | De-Ice System | Anti-Ice System |

|---|---|---|

| Gulfstream G700 | Pneumatic Boots | Engine Bleed Air |

| Bombardier Global 7500 | Electrical Heating on Wings | Engine Bleed Air and Electrical |

| Cessna Citation Longitude | Pneumatic Boots | Anti-Icing Fluid |

Comparison with Competing Aircraft

When compared to competing models in the executive aviation market, the de-ice and anti-ice systems on modern aircraft offer greater reliability and efficiency. Below is a comparative table:

| Aircraft | Approximate Price | De-Ice System | Anti-Ice System |

|---|---|---|---|

| Gulfstream G700 | $75 million | Pneumatic Boots | Engine Bleed Air |

| Bombardier Global 7500 | $73 million | Electrical Heating | Engine Bleed Air |

| Dassault Falcon 8X | $65 million | Anti-Icing Fluid | Electrical Heating |

Conclusion

The use of de-ice and anti-ice systems is critical to ensuring safety and efficiency in executive flights. Modern aircraft are equipped with advanced technologies that make the ice prevention and removal process more automated and efficient, ensuring the aircraft’s protection even under the most adverse conditions. For those looking to acquire a high-performance executive aircraft, Goal Aircraft offers a range of models equipped with the best ice protection systems available on the market.

Call-to-Action

Interested in purchasing an aircraft equipped with the best de-ice and anti-ice systems? Visit our website goalaircraft.com and explore our inventory of executive aircraft. Contact our specialists for more information.